SparkFun Tour

- Jack Plantz

- Sep 5, 2018

- 3 min read

For class today we met at the headquarters of Sparkfun Electronics in Niwot and got a full tour of their factory as well as an inside look at what the job of a creative technologist looks like.

SparkFun is an electronics company founded in 2003 by CU student, Nate Seidle, who broke a power supply in his dorm room and found it incredibly difficult to order replacement parts. After communicating with a factory in Bulgaria via fax machine, he decided to order 10 power supplies so that he would have extras to sell to his friends, saving them the difficulty of tracking down their own parts. After graduating, Nate decided to start a company based on improving people's accessibility to electronics by selling components online. Now Sparkfun has over 2000 open source components and boards designed to make electronics projects easier and more capable than ever before.

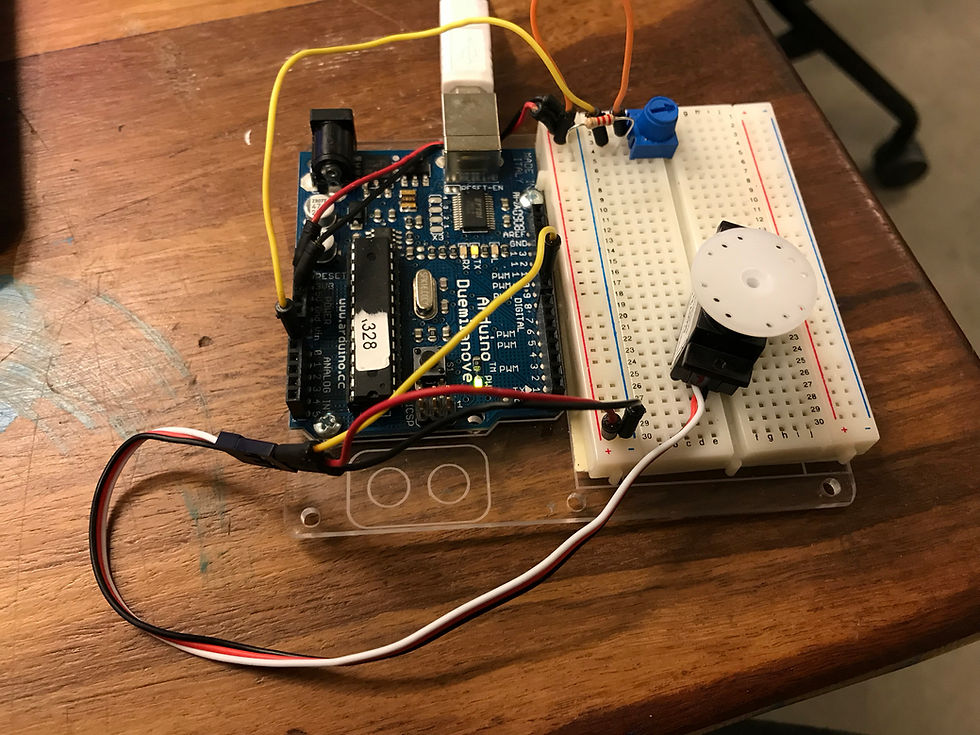

Most of SparkFun's products are Arduino based control boards, or sensors and peripherals designed to be used with Arduino boards. We got to see the entire production path of SparkFun's flagship microcontroller, the RedBoard, all the way from a blank circuit board to finished product.

The board itself is manufactured in China, then the electrical connections are given a thin coating of solder paste with a precisely cut stencil that allows all of the connections to be covered with one squeegee wipe of solder. Then a pick-and-place machine places the correct components onto the board (or usually a sheet of identical boards). These machines move incredibly quickly and precisely and vastly increase the rate of production of these circuit boards. After all the components are on, the board rides through an oven heated to very specific temperatures that melt the solder and make electrical connections permanent, but are not so hot that they damage the components on the board. Now all that's left is testing for quality control, which is accomplished by plugging the boards into specially designed test-beds that can analyze the performance of every pin and component on the board.

After our tour of the production floor, we got to see the creative technologists' desks including our professor's: Melissa Felderman. The creative technologists use all of SparkFun's different products and make projects and tutorials with them. They technically work for the marketing department of SparkFun because their tutorials are meant to inspire people to want to make similar projects, which they'll need to buy SparkFun boards to be able to do. Melissa (or Feldi, as she's apparently called at SparkFun) had a new project using addressable LEDs to make a light sculpture with laser cut transparent acrylic.

Next we went to SparkX, a newer division of SparkFun whose goal is to rapidly innovate and create new products without fear of failure. SparkX was started as a way for Nate, founder and former CEO to get back to engineering and innovation, rather than the day to day business of running the company. Here the make all kinds of experimental boards, including a puzzle board whose purpose is intentionally obscured from the user. The goal is to hack on it until you can figure out what the board is and what it does!

Overall I really enjoyed our tour of SparkFun. Everyone we met seemed excited to work there and enthusiastic about whatever project they were working on. The lobby was full of incredibly inspirational projects using all kinds of SparkFun products. I can't wait to get further into this Object class so I can start on projects of my own!

Comments